Understanding China Lathe Machine Parts: Quality, Innovation, and Industry Impact

The machining industry is undergoing rapid transformation, with China leading the way in the production of lathe machine parts. As a crucial component in various manufacturing processes, these parts play a vital role in enhancing productivity, efficiency, and overall performance. In this article, we will delve deep into the world of China lathe machine parts, exploring their significance, quality standards, and the innovations driving their development.

The Essential Role of Lathe Machine Parts in Modern Manufacturing

Lathe machines are foundational to the manufacturing sector, allowing for precise shaping and finishing of materials such as metal and plastic. The components of these machines, including the spindle, carriage, and cross-slide, significantly affect machine performance. Understanding the function of these parts is essential for stakeholders in the metal fabricators industry.

- Spindle: The heart of the lathe that rotates the workpiece.

- Carriage: Moves the cutting tool in a longitudinal direction.

- Cross-slide: Enables horizontal movement of the cutting tool.

The synergy of these parts contributes to the creation of intricately designed products, making them indispensable in sectors ranging from aerospace to automotive.

Quality Assurance in China Lathe Machine Parts

When it comes to lathe machine parts, quality is non-negotiable. As a metal fabricators industry leader, Deepmould has made considerable investments in quality assurance protocols to ensure that each component meets international standards. This commitment to quality is evident in several ways:

1. Rigorous Testing Standards

Every lathe machine part manufactured undergoes a series of rigorous tests, including:

- Dimensional Verification: Ensuring all components fit within specified tolerances.

- Material Testing: Assessing the durability and strength of raw materials.

- Performance Testing: Evaluating how each part performs under real-world conditions.

2. Skilled Workforce

The expertise of workers involved in the manufacturing of China lathe machine parts is paramount. Deepmould employs a team of qualified engineers and technicians who are skilled in the latest manufacturing techniques and technologies. This level of expertise ensures that every part produced not only meets but often exceeds the expected quality benchmarks.

3. Compliance with International Standards

Deepmould’s manufacturing processes adhere to international standards such as ISO 9001, which certifies consistent quality management systems. This compliance inspires confidence in customers seeking reliable lathe machine parts.

Innovations in Lathe Machine Parts Manufacturing

The landscape of lathe manufacturing is continuously evolving due to advancements in technology. Here are some key innovations driving the industry forward:

1. Computer Numerical Control (CNC)

CNC technology has revolutionized the production of lathe machine parts. By automating the machining process, CNC tools allow for enhanced precision and efficiency. Parts can be produced with minimal human intervention, reducing the chances of error and ensuring consistent quality.

2. Advanced Materials

Manufacturers are exploring new materials that offer enhanced performance characteristics. For example, high-speed steel and ceramics are being utilized to improve tool longevity and reduce wear and tear, inevitably leading to cost savings in production.

3. Additive Manufacturing

The rise of 3D printing technologies has begun to influence the manufacture of lathe parts. Rapid prototyping and manufacturing of complex geometries are now achievable, reducing lead times and allowing for better customization to meet client specifications.

Why Choose Deepmould for Your Lathe Machine Parts?

When it comes to sourcing China lathe machine parts, partnering with a reliable manufacturer is essential. Here’s why Deepmould stands out in the metal fabrication space:

1. Comprehensive Services

Deepmould provides a full suite of services, including design, manufacturing, and testing, making it a one-stop shop for all your lathe machine part needs. This integrated approach simplifies supply chain management and enhances communication.

2. Custom Solutions

Understanding that each client has unique requirements, Deepmould offers tailored solutions to meet specific needs. Whether it’s a custom part design or a unique material requirement, their team is equipped to deliver.

3. Global Reach

Deepmould has established a robust distribution network that spans across various continents. This global presence ensures that clients can receive their lathe machine parts on time, irrespective of their location.

Applications of China Lathe Machine Parts

China lathe machine parts find their application across an array of industries. Below are some notable sectors utilizing these components:

- Aerospace: Precision parts are critical for aircraft manufacturing and maintenance.

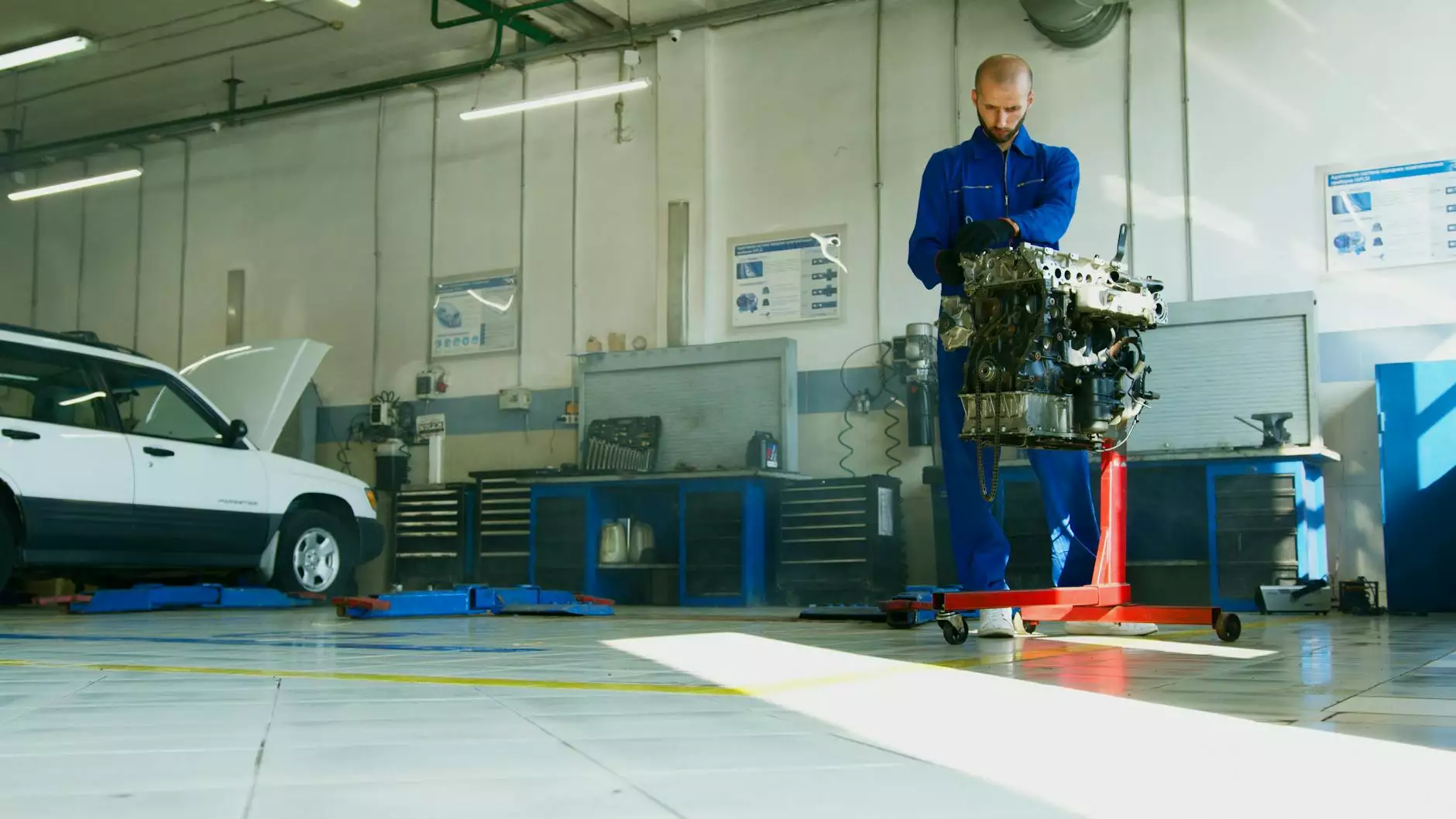

- Automotive: Lathe parts are essential for engine components and assembly lines.

- Electronics: Reinforced materials are used in devices requiring ultra-precision.

- Manufacturing Machinery: Vital for producing equipment used in various manufacturing processes.

The Future of Lathe Machine Parts Manufacturing

The future of China lathe machine parts is poised for exciting developments as technology and innovation continue to shape the landscape. Companies like Deepmould are committed to staying ahead of trends, investing in research and development, and embracing new manufacturing technologies. Here’s what to expect:

- Enhanced Automation: Increased reliance on robotics and smart manufacturing systems.

- Sustainability Initiatives: Development of eco-friendly manufacturing practices and materials.

- Digitization: Use of IoT technologies for real-time monitoring and data analysis to improve manufacturing precision.

Conclusion

In conclusion, the relevance of China lathe machine parts in the manufacturing sector cannot be overstated. With companies like Deepmould leading the charge in quality assurance, innovative practices, and comprehensive service offerings, the future looks bright for all stakeholders involved. Whether you are in the aerospace, automotive, or electronics industry, choosing the right manufacturer for your lathe machine parts can make a significant difference in operational efficiency and product quality.

By partnering with a dedicated supplier like Deepmould, you can ensure that you are equipped with the best quality components that drive your business forward. Embrace the power of innovation and quality with Deepmould’s exceptional delivery of lathe machine parts that meet and exceed your expectations.